I love three-day weekends! (Who doesn't??) Today afforded me a chance to make a mess in the garage.

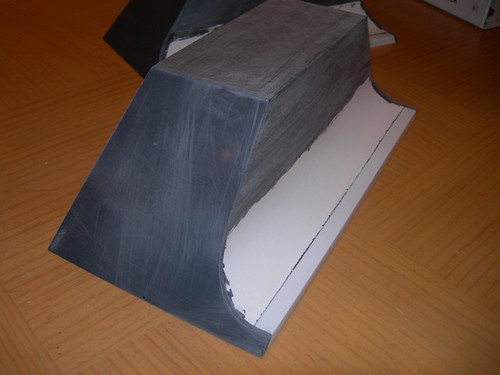

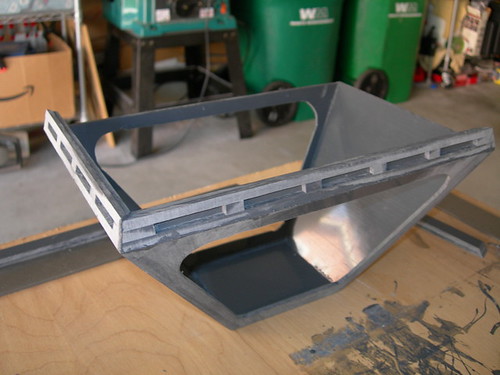

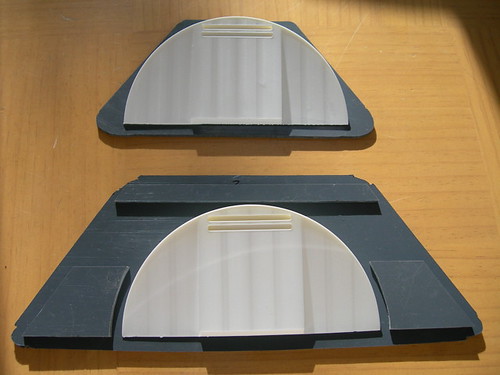

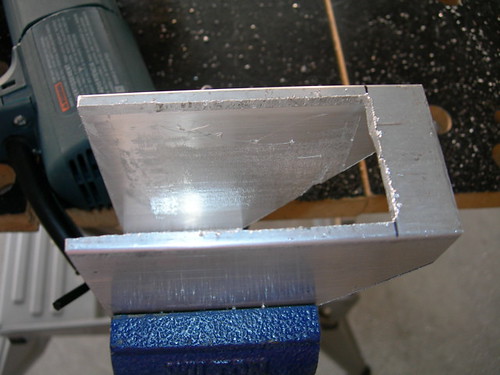

I pretty much picked up where I left off yesterday with the outer feet. The PVC glue had dried overnight, so I used the Dremel with the cutoff wheel to hack down most of the overhang on the edges of the outer feet. Then I used the Dremel drum sander to bring the overhang to a minimal distance so that I can sand off the rest by hand.

After the trimming, I sanded the top side of one of the outer foot shells nice and flat. I also sanded the flat edges on the bottom of the curved side on both foot shells, so that I could be sure that the lengths of the bottom strips could be measured accurately.

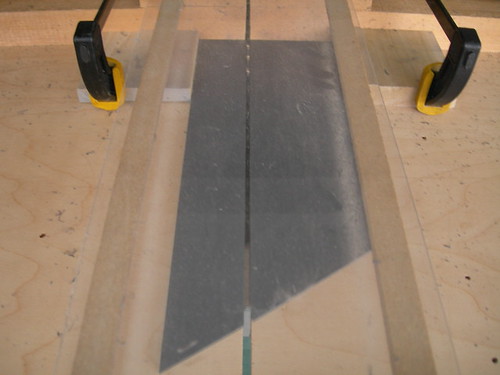

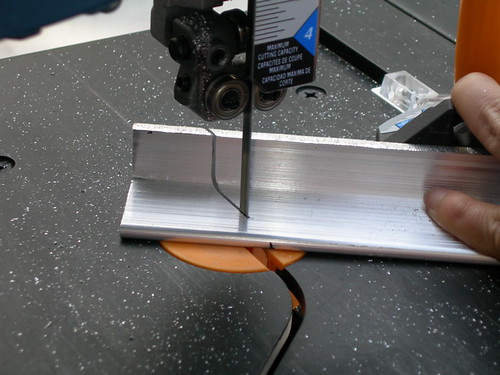

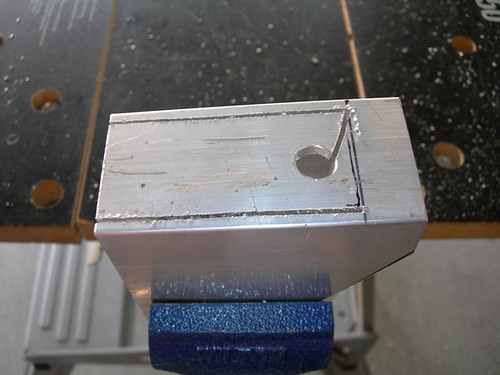

Recall that the bottom strips were cut too long intentionally, and now is the time to cut them to the correct length.

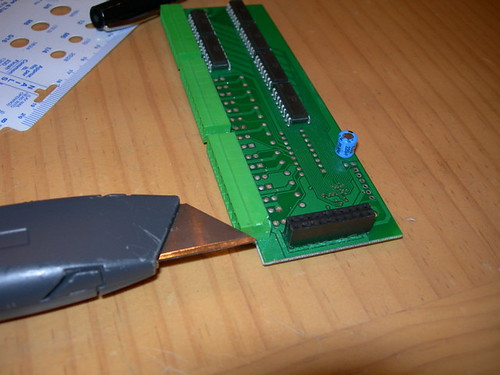

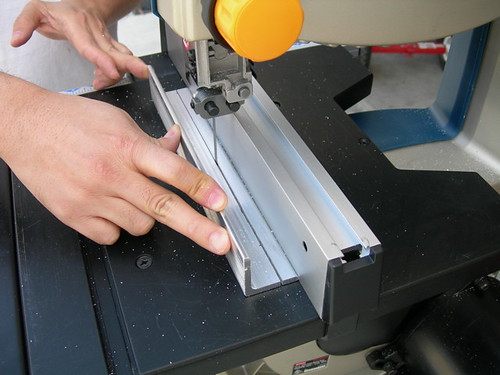

As Mike showed me on Saturday, the idea is to locate the midpoint of a bottom strip, and the midpoint of the corresponding edge of the foot shell. These two points will line up when the strip is glued to the foot. Once the centers are lined up, I then used a razor blade to lightly mark only the left edge on the bottom strip to trim. (The strips were trimmed upside-down, so the cut itself appears on the right.)

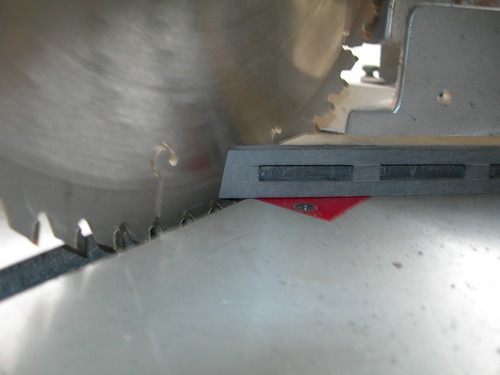

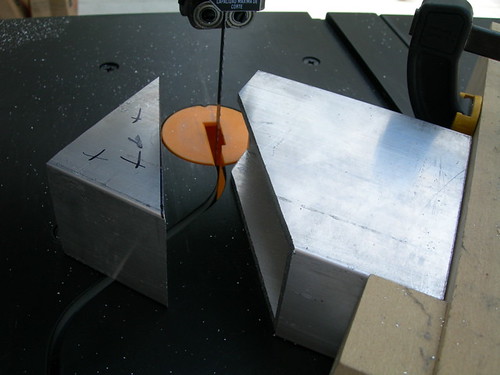

The top and bottom edges of the bottom strips have a 12 degree beveled edge, so I used a strip of wood that Mike cut on Saturday that also had the 12 degree tilt, to rest the PVC strip on. This helps to prevent the PVC from chipping as the cut is being made. I trimmed the strip down at a 45 degree angle a little at a time, until I hit my mark.

With the left sides trimmed, later I can again match the bottom strip to the corresponding foot shell edge, and make another notch for the right end, and trim. This time, I should have a match at both the left and center points on both the bottom strips and the foot shell edges, but the important thing is to align the left edges before marking the right edge. This ensures the correct length. (I ran out of daylight, otherwise I would have done it today.)

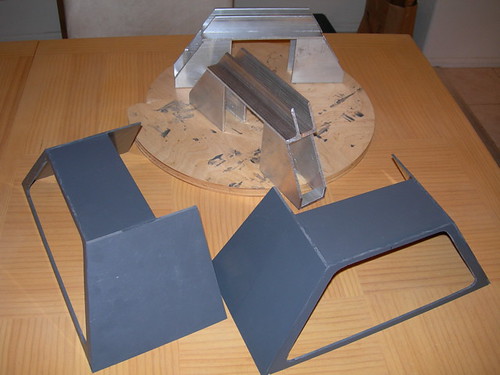

There's still a fair amount of work left on these foot shells, but they are definitely taking shape.