Okay, time to 'fess up. I'm suffering from a severe crisis of confidence in my drivetrain build. I'm moving forward (I purchased more 3/4" diameter steel for axles and shaft adapters today), even as I think I need to retreat. What's the problem? Well, where to start?

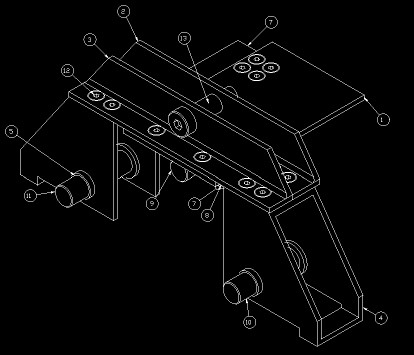

First, I should back up a bit and explain what my approach is. As I've written, I'm working on a modified version of the Heath (MacMillan) & Alex (Kung) drivetrain. I have chosen this drivetrain because it is designed to work with the Saturn windshield wiper motors, and it is a generally nice 2-wheel (per foot) drive. I've chosen the Saturn motors because I like the torque and worm-gear nature of the drive, plus it is relatively inexpensive and readily available. I realize it cannot free-wheel, but I like the fact that the droid won't roll downhill on its own either.

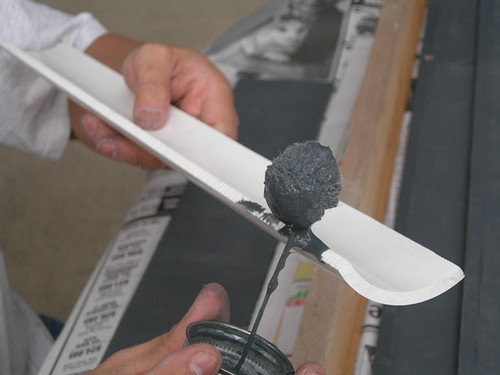

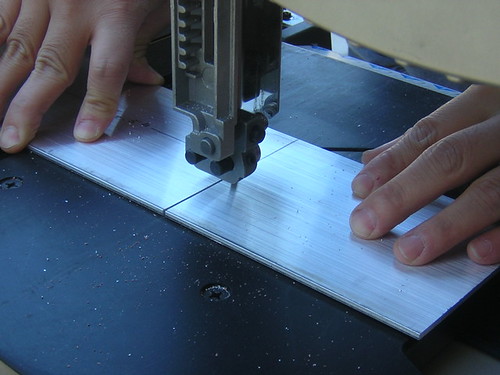

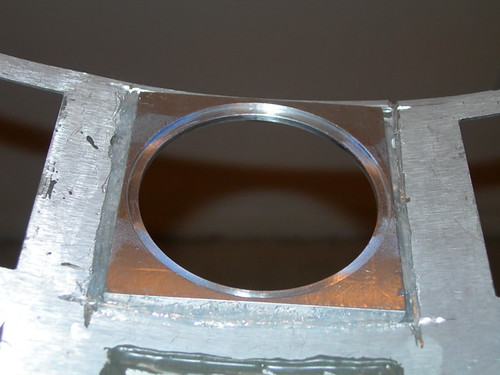

I was planning on using some nice bearings for the axles, but I'm finding that the outer diameter is too large to fit the 2x4. The bottom hangs over the lower cut, where the wheels are exposed to ride on the ground. I can't really raise the bearings, because that will raise the axles, which will raise the wheels, and potentially cause them to run into the inner surface of the 2x4. So I think these bearings are a no-go for this reason alone (but there's more).

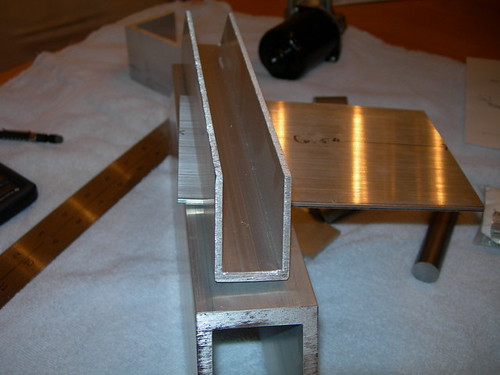

The aluminum 2x4 that I'm using as the main body of the drivetrain has a 1/4" thick wall, while the original H&A design called for a 1/8" thick wall. The bearings won't fit with the standard wheel I'm using, there's no room. In fact, there really isn't much room for a smaller bushing in there either, I'd have to file it down quite a bit.

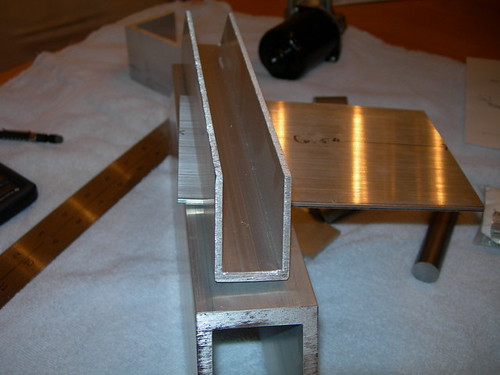

Next problem. The H&A design calls for two "L" channels on top, but I have a single "U" channel. This does a poor job of accommodating the main bar that the motor mount hangs from. Furthermore, this channel must align with the top opening in the foot shell, and I have doubts that this is even possible with the channel I've chosen, though I'm not certain.

There are a boatload of problems beyond the ones I just listed, including (but not limited to):

- I did not cut out most of the siding of the 2x4, so there's no way to slide the main bar under the top of the 2x4 like the H&A plans dictate. The bar would have to ride on top.

- The main bar is 1/16" thinner than specified in the plans (is 1/8" thick, should be 3/16" thick). So far I have not found 3/16" thick stock that is 4" wide. This probably isn't a really big deal, but it means that the measurements for various holes will have to be adjusted by 1/16".

- If I were to proceed with the current approach, lots of other measurements will have to be readjusted. Instead of the motor mount hanging from below the top of the 2x4, it will hang from above it (an additional 1/4" of readjusting measurements). Thus lots of other locations for holes in the motor mount area need to be adjusted correspondingly.

And the list goes on, probably including stuff I haven't even thought about yet.

I'm seriously considering scrapping most of the work I've done so far, and starting over with a 1/8" thick-wall 2x4, with cuts more closely following the H&A design. I need to study all of this some more.

It's really frustrating. Once this and the foot shells are done, the droid is ready for wire-up and motors, and then it will be complete. But I have no idea how long this is going to take. Staring at it nightly and shaking my head doesn't seem to be making it go any faster. This is the 80/20 rule in all its glory.

Maybe if I only stare harder...