Last night I called Mike to see if I could come over so we could work on straightening out my back door panel, to which he replied, "Dude, I already did it."

So instead of hoping we'd have enough time to work on the back door, I got to see the results of the labors of Mike and his elves. They do good work!

Some of the panels popped off and are just resting in place, but the shape of the door and the panels seem to be about what they used to be.

In the meantime, Mike is preparing his droid #2 for a special event that it will be involved with soon. Perhaps as a Jedi Knight?

Speaking of his droid #2, you may recall back in

December 2011 I was working the dome electronics for Mike's dome #2, in case it was needed for the

Verizon commercial. I ran out of time, and a few components, such as the PSI logic boards and the entire front logics, were merely taped into place with masking tape.

So we pulled those out and went to work on a more permanent arrangement. Mike cut some circles from 1/8" PVC to which the small logic boards will be attached.

I drilled mounting holes for the electronics boards, and then used PVC glue in three locations around the circumference of the PVC disc to attach it to the segment of PVC pipe used for light diffusion. The small amount of PVC glue will hold the discs in place, but they will be removable if necessary.

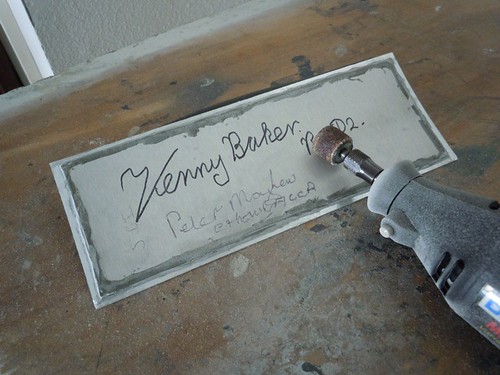

Meanwhile, Mike cut down some #6 screws to more permanently mount the front logics. Never miss an opportunity to photograph sparks!

With everything back in the dome, we fired it up. The lights all work, even when the dome is upside-down. And I know a thing or two about upside-down droids.

Back home, I tried the door on the droid, to make sure the holes for the screws lined up okay with the brackets that receive them on the frame. They seem to. And you can see which panels need to be JB Welded back in place. For now, it's a door with windows.

So as you can see, I still have my work cut out for me, but things are in a lot better shape than they were a couple of weeks ago. Thanks again to Mike for all the help with this.