Tonight I was going to start prying the panels off of the dome. The panels are held in place with 3M Very High Bond tape. The first pie panel I tried to remove didn't want to budge. I barely got it to move, and never did get it out. Maybe this is telling me that I should just leave well enough alone.

The "problem" I'm trying to solve is that the paint job does not have a nice shine to it, nor is the color quite as saturated as it should be. It's passable, but it could be better.

I may try using some automotive rubbing compound to see if I can get the panels shinier, but right now I'm not sure what I'm going to do, if anything.

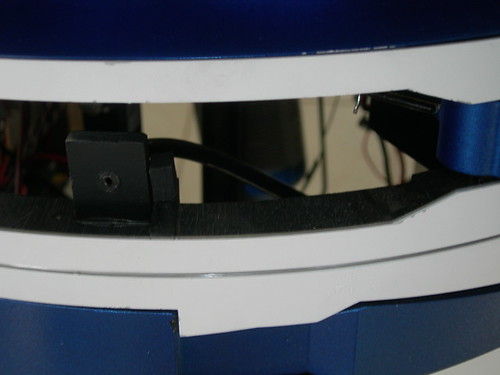

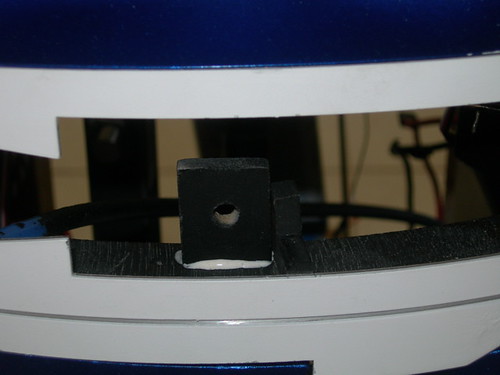

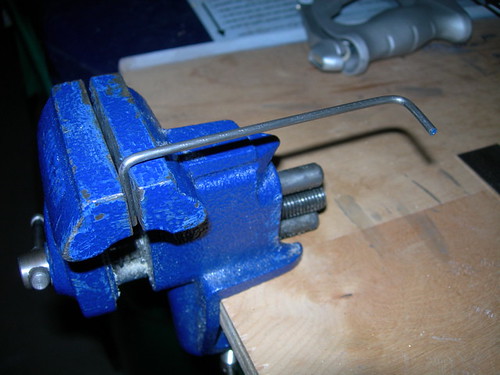

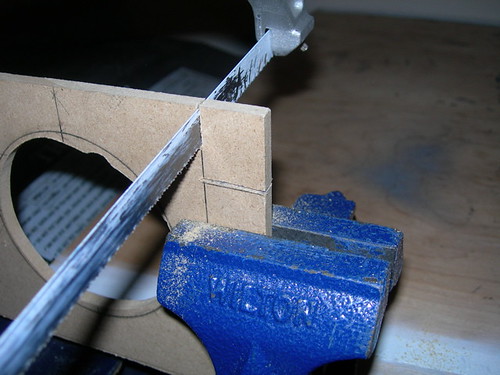

In the meantime, I would like to try recutting the top piece of the door frame on each side of the center foot. This piece had to be partly Dremeled down to allow the ankle bolt to be inserted and removed. Now that I've redrilled the ankle bolt hole lower, I should be able to recut this piece and replace it, without having the ankle bolt run into it anymore. Maybe I'll work on that.

I think I miss building.