Today I returned to work on the foot shells for droid #2. This time it was time to cut the mounting tabs that are used to keep the doors in place on the foot shells.

Unfortunately, the aluminum outer foot shells are less than perfect, so mounting the doors to be precisely centered really isn't possible, although it doesn't look too awful.

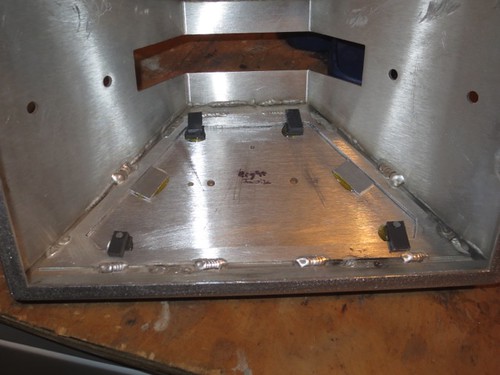

I taped the doors in place, as I'll need to have them stay put later, when I permanently attach the mounting tabs.

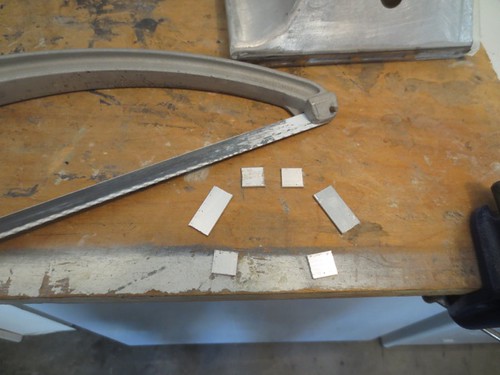

I am using 1/8" thick PVC segments on the backs of the doors to act as mounting tabs. The door frame is only 1/16" thick, so in theory I will need to double-up the thickness of the door frames. I cut several 1/16" aluminum tabs.

The two longer, diagonal tabs are to be mounted on the back of the door, to help keep the door centered in the frame. The four smaller tabs are to be mounted on the door frame, which is part of the outer foot shell, and not part of the door. This will make their height 1/8" above the back of the door, allowing me to stack a pair of 1/8" PVC segments on the back of the doors to clear them, but still provide a snug fit. I won't be sure I'll actually need the four smaller tabs until I do some test fitting. I probably should have waited on cutting those, but it's no big deal.

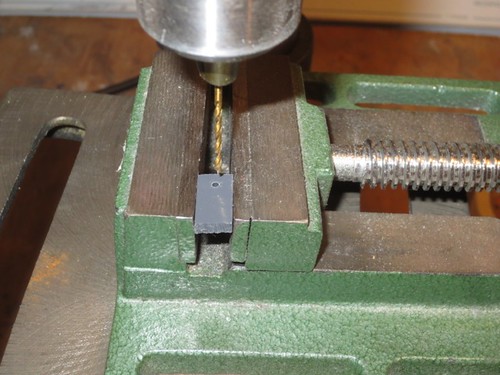

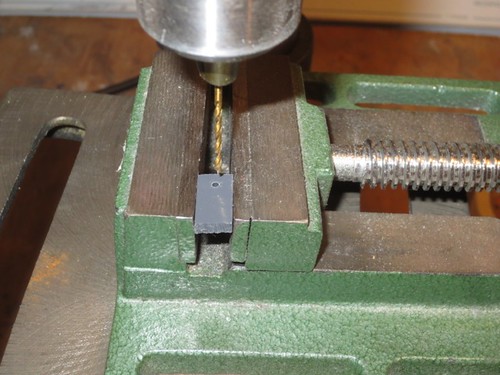

Next, I cut many small segments of PVC strips, and I drilled 1/16" diameter holes into the ones that will go along the bottom of the backs of the foot shell doors.

Using my needle-nose pliers, I cut six #16 nails down to 1/4" in length, long enough to go through two layers of the 1/8" PVC strips.

The nail acts as a pivot point, that will allow me to lock and unlock the doors on the door frame.

For each of the three feet, there are pairs of stacked PVC segments with nails as pivot-points for the bottom of the doors. Similarly, there will be stacked PVC segments for the tops of each door, but these will not pivot.

This will all be clearer when the tabs are attached, and it is also shown in the builds of the A&A foot shells I did earlier, as well as the build of the foot shells for droid #1.