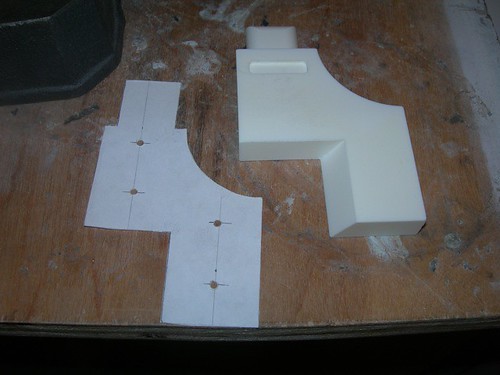

First, I marked where I wanted the mounting screws to be located on the foot shell.

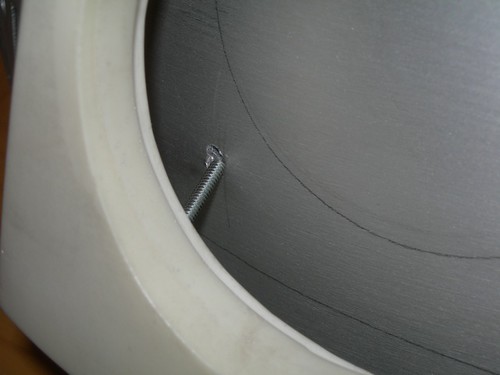

Then, I drilled for a #4 screw.

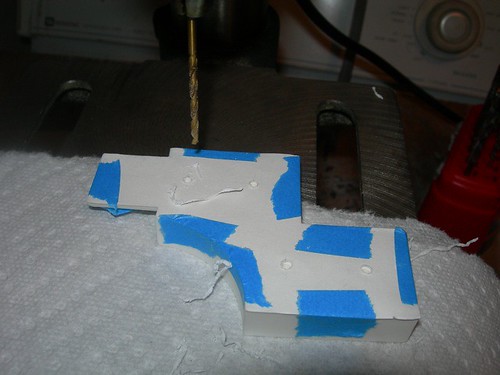

Next, I taped the foot strip so that it would be centered below the channel on the foot shell, and drill pilot holes from behind with the hand held drill.

I used the drill press to drill about 2/3 deep into the back of the foot strip. I don't want to go all the way through if I don't have to. I then tapped the hole for a 4-40 screw. I think the hole is deep enough that the screw will have enough threads to keep the foot strip tight against the foot shell.

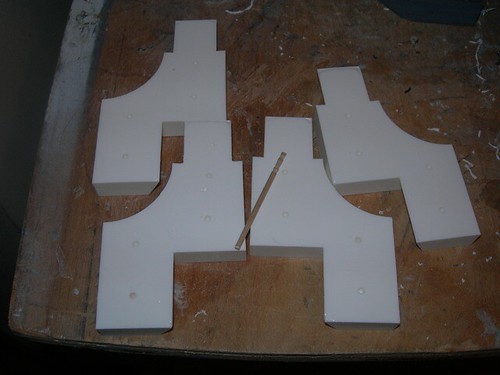

I repeated for the other screw, and the foot strip seems to be holding well.

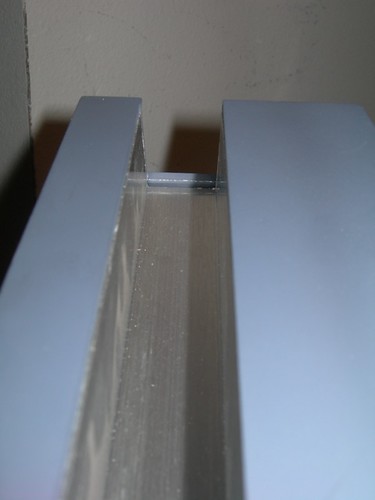

Next, I used the pre-cut holes in the A&A foot shells to determine where to drill the holes in the foot strip for the knurled hose fittings. I drilled a couple of pilot holes while the foot strip was screwed down in place.

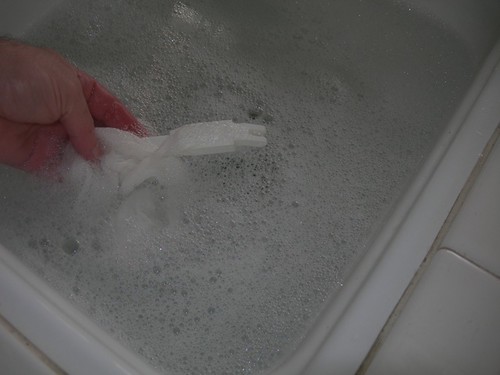

I then removed the foot strip from the foot shell and drilled the pair of 5/8" holes on the drill press, using WD-40 to keep the aluminum foot strip and drill bit lubricated.

Finally, it was time to try it out on the foot shell. The holes seem to match up, although I think the holes are slightly off-center on the A&A foot shell. I may decide to drill the next one such that the holes are more perfectly centered on the foot strip, even if that does not match the holes in the foot shell.

I also created another cool science fiction worm.