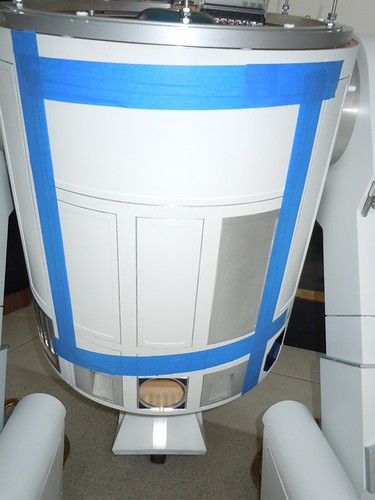

The first thing I needed to do was tape the back door in place. I carefully lined it up to where it should be, and taped it down with the blue painter's tape.

One thing I realized is that the pieces that I cut that get glued to the door won't sit flush without some work. The radial angle of the ribs requires some sanding.

I actually cranked out the math, and marked where to sand.

After a little while, I had the blocks sanded.

The fit is better on both sides now.

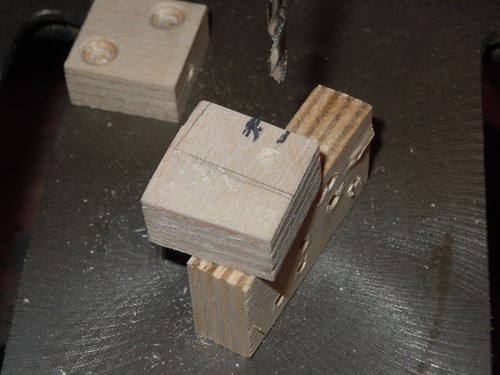

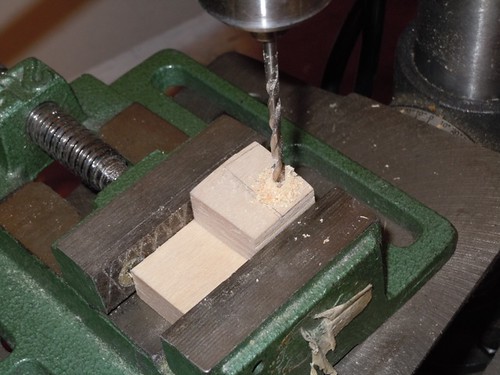

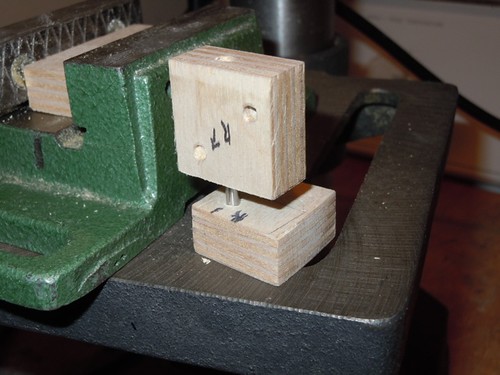

Next, I needed to drill matching holes that will meet up with the steel dowel pins and magnets. This isn't as bad as it looks, I'm merely using the top piece as a template of where to drill the middle piece for the steel dowel pin. I lightly spun the drill chuck by hand to make a mark.

I drilled the 1/8" wide hole, 3/8" deep on both door pieces.

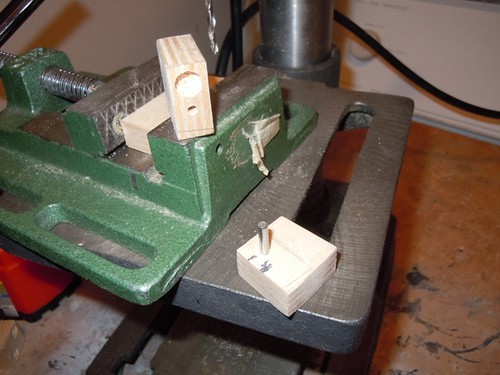

The steel dowel pin can now match the hole on the piece that gets attached to the frame.

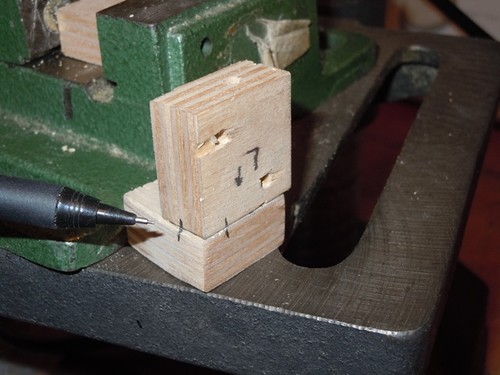

Then, I needed to match the magnet holes on the frame pieces with holes that need to be drilled for matching screw heads. I placed cross-hair marks at 90 degree angles that help show where the center of the hole is.

With the steel pin locking the two pieces of wood together, I translated the markings from one piece of wood to the other.

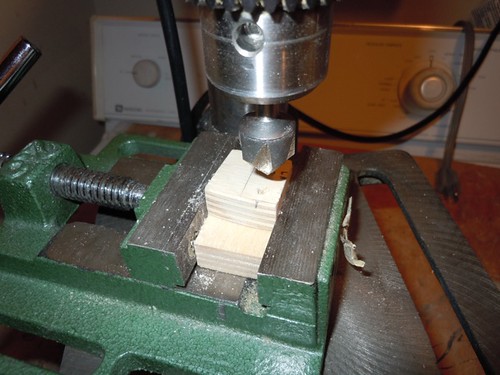

With the cross-hairs as my guide, I drilled and countersunk the hole for the screw that will attract the magnet.

That's as far as I got tonight. The magnets and screw heads should line up, as should the steel dowel pins and their corresponding holes.

I still need to cut the screws down to size (they stick out of the back), and then I can start gluing the door pieces to the inside of the door.

2 comments:

Victor, is it that the rear hatch drops into the bottom wood blocks via the pins and the magnets are on the top 2 mounting blocks? What type of adhesive are you using to mount the wood blocks to the alum. rear hatch? Have you found that this system is pretty effective?

alan

Alan,

Great question. You have it right, and you are really paying close attention.

I accidentally discovered with droid #1 that JB Weld does a good job of adhering wood to aluminum.

To this day I still have evidence on the back door of droid #1 of where I used a wooden tongue depressor to help evenly apply pressure when I clipped the coin returns in place.

This can be seen in the lower right-hand corner of the last picture on this page:

http://vfranco.blogspot.com/2007/05/glued-in-cylinder-holders-built-manual.html

It is quite possible that my efforts will not work as intended. If it ends up being a big mess, I will abandon this approach, and just go with the four screws that I use on droid #1.

-Victor

Post a Comment