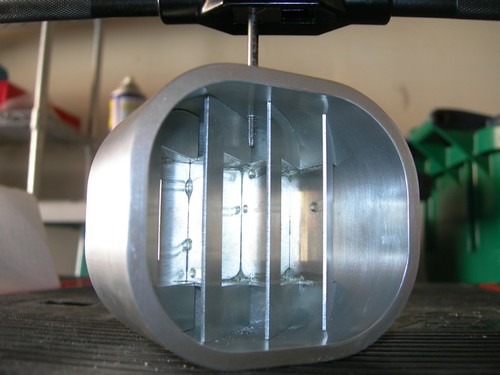

Tonight I worked on installing the octagon ports.

First, I cut a 1.25" strip of 1/8" MDF, that will serve as the mounting pieces.

Next, i measured how tall each strip should be to reach from the rib above the octagon port, to just below the middle of the octagon port.

I prepared to drill the mounting holes into the back of the octagon port. The middle part of the octagon port is 0.60" tall, I set the drill press to drill 3/8" (0.375") deep, to be on the safe side.

I used strapping tape to secure the MDF holder, and drilled through the MDF and octagon port as a pair.

I also used the MDF as a template for drilling the holes in the MDF holder for the other octagon port.

I tapped the holes in the back of the octagon port for 4-40 screws.

Next, I measured and marked where to drill the mounting hole for the MDF holder to hang from the rib above the octagon port, and also colored the area black that can be seen through the ribbing of the octagon port.

Finally, it came time to mount the part.

Hey, the top of the octagon port isn't sitting flush with the skins!

Okay, no problem. I'll add a 1/8" MDF shim layer.

Hey, the bottom part of the port isn't fitting all that snug either!

Okay no problem, I'll jam something behind the lower part of the octagon port. About 1/16" of MDF should do. This is a temporary solution, I'll probably glue a small piece of styrene to the back of the MDF holder.

Okay, now things are looking reasonably good.

I'll probably work on installing the front vents next. That setup is a bit more elaborate.