Today I cut the shoulder discs and glued up the front vents.

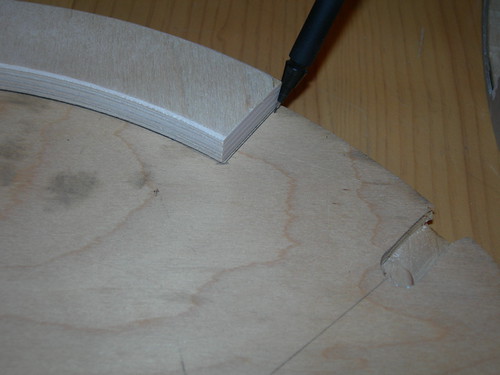

I picked up where I left off yesterday with the shoulder discs, by rough-cutting the 6.25" x 3/4" circles with a jigsaw.

Next, I drilled a 5/64"-diameter hole straight through the center of each circle, just wide enough for a nail to fit.

I then placed the nail through a similarly drilled hole in a board, so that the shoulder disc can sit on top of it on the router table.

I used a routing technique Mike Senna taught me on droid #1 (and that is described on the R2LAIII DVD). With the disc in place, and everything loosely clamped, I edged the disc into the spinning router bit, until I shaved off enough material that the router bit touched the circle I drew on the wood. At that point, I turned off the router and clamped everything down. Then I turned on the router again and spun the disc on the nail, until all the rough-cut edge was shaved down to the 6.25" diameter.

Repeat, and two shoulder discs are ready for marking-up for the gas pipe flanges (at some future date).

In the evening I turned my attention to the front vents.

I hope to glue up the frame next weekend, so I want to finish my minor trimming on the frame as soon as possible. One of the last things I need to do is trim the two center vertical ribs, to accommodate the front vent harness assembly. I can't make the cuts on the ribs until I've actually built the assembly, of course. Step zero in the harness build is to put together the front vents.

Like last time, I used Loctite (which my spell-checker thinks is "Lactate") to glue the pieces together.

Unlike last time, this time I had enough sense to spray some accelerator to instantly dry the glue.

Top vent done.

Next, the bottom vent. I used the surround to guide the pieces into place, and glued them to the backing plate.

Then I removed the surround and glued the slats down, and then applied accelerator again.

Both front vents are ready for the harness build, which I hope to get to tomorrow, since I have Presidents Day off.