R5 Dome: Check.

Kelvin: Check.

Tonight I went over to my friend Kelvin's place to work on getting the aluminum struts fitted into the R5 dome. The dome arrived with some resin struts already in place, but since I purchased the COM8 aluminum R5 dome kit a while back, I figured I might as well use the aluminum pieces.

The resin pieces were held in place with small nails at the top and bottom. We pulled those out.

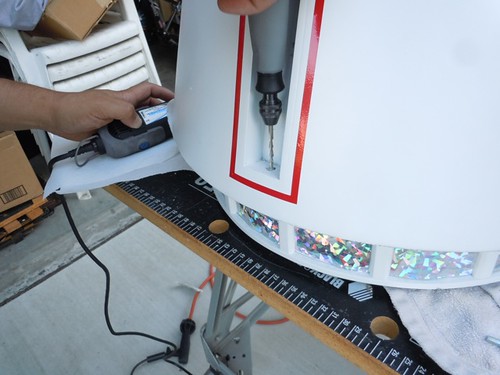

Next, Kelvin used the flexible Dremel attachment to widen the nail holes, to accommodate #10-32 machine screws that will be used to secure the aluminum struts. The Dremel chuck won't take a 0.190 drill bit, so he had to use a smaller bit and do his best to create a clean circle.

After we widened the bottom holes, we flipped the dome over and worked on the top holes. Note that the Dremel does not fit completely into the breadpans, so the holes are slightly angled, which is suboptimal, and will require a bit more cleanup work later.

The aluminum struts are just a hair too long to fit into the breadpans, so we used a trick Mike Senna showed me for the left and right struts. We wrapped some tape around the top of the shaft, inserted it into a drill press, and then used sand paper on the bottom to shave a few fractions of a millimeter in length.

For the rear strut, there was enough material to remove that we decided to use the belt sander.

And that's where we left things. The struts now fit into the breadpans, but the holes need to be cleaned up a bit to be more vertical, since they were drilled at an angle. I hope to get to that shortly.

No comments:

Post a Comment