The center leg rails need several holes drilled into them. A pair of 3/8" holes are drilled through the rails and legs, such that a pair of 3.5"x3/8" bolts can secure the center leg to the rails.

The first step is to mark the location of these 3/8" holes. Most of the center leg is hollowed out, but the outer inch or so of each side is solid. The holes are located toward the solid, outer area. I use the hollow part of the center leg for the pipes I use for the manual droid lift, so I don't want to obstruct the hollow area with the bolts.

Once the rail has been marked, it's time to drill the holes.

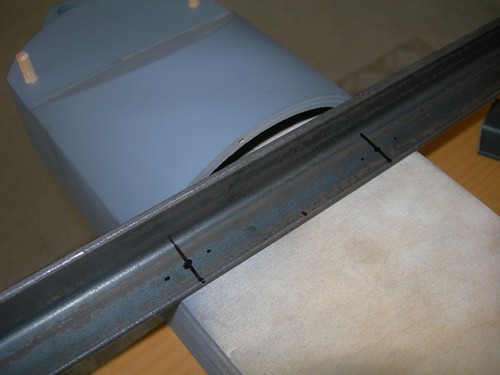

The rails will face back-to-back, with the leg between them. Since all the holes need to line up, I used the holes in the first rail as a template for where to drill the holes in the second rail. I clamped the rails to a flat board and drilled through the holes in the rail on top, and through the rail on bottom.

At this point, I was ready to drill the holes in the center leg, but I was reminded that my drill press is only capable of drilling holes 2" deep or less, and the leg is 2.25" thick. I could have started the hole on the drill press and finished it with a hand drill, but I knew my friend Kelvin's drill press could handle this, so I gave him a call and he said I could come over and drill the holes there. Good thing he lives nearby.

Again, one of the rails is used as a guide for drilling the holes in the leg.

Everything lines up perfectly, fortunately.

Finally I measured and marked where to drill the holes for mounting the rails to the bottom of the frame. These holes are 5/16" in diameter. I was careful to ensure that I could fit a socket head on the rail for tightening the bolt from the top. Drilling the hole too close to the vertical side of the rail would inhibit access. Each 5/16" bolt will screw into a t-nut that will be inserted into the bottom of the frame soon.

One hole per end of each rail is drilled.

With the drilling of the rails out of the way, I wrapped up by drilling and pinning the flanges to their respective pipes. The pipes are already JB Welded in place, but this adds extra reinforcement to keep the pipes from unscrewing from the flanges.

The first step is to drill four 1/8" diameter holes around each flange/pipe combination.

Then I whipped up a batch of JB Weld and wallowed each of the pins in it, before inserting them into the holes I just drilled.

Finally, I inserted the pins in the holes. Some pins required a light tap with a hammer. The pins are steel, 3/4" long and 1/8" in diameter.

If I have time tomorrow, I may tackle the drilling of the frame to secure the rails to it. We shall see.

No comments:

Post a Comment