Tonight I prepared a small template to help me route the corners of the button and hydraulic pockets on the horseshoes. The current radius is 1/4", I plan to reduce it to 1/8".

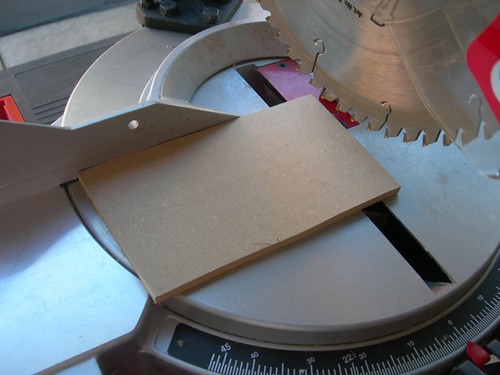

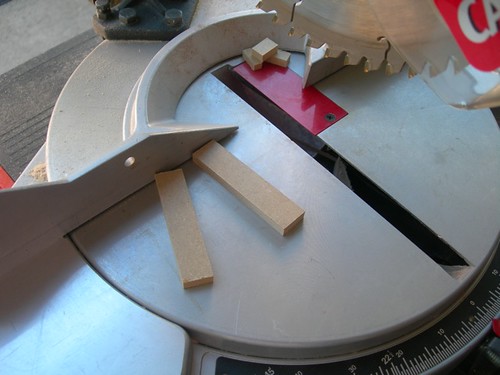

I started with a small piece of MDF, and cut a couple of strips on the chop saw.

Next, I glued the two strips to each other at a 90 degree angle.

I'll let this dry overnight. Once ready, I will nail the guide to the back side of the horseshoe, and use a 1/4" diameter flush-cut router bit to sharpen each corner on the router table.

If I wanted to get really fancy, I suppose I could have made a guide that lets me cut multiple corners at once, but I didn't do that. Instead, I will need to move this guide and route each corner, one at a time.

Once all this is done I can move on to finishing work on the legs and horseshoes.

5 comments:

When you move the guide you may have a hard time aligning it with your last cut which will result in a "step" where the router bit meets with the previous cut....(?)

But good idea to make a template like that.

See ya at R2LA!

Russell

You are probably correct, and I may end up botching this. That's why the weblog documents my misadventures! I'll try to be as careful as possible, but we'll see how it goes.

I may still modify the template to do the entire outline of the pockets, but I'm worried I won't hit the dimensions perfectly on that either.

-Victor

The more I thought about this, the more I realized what Russell wrote should be addressed. So I redid the templates to surround the full perimeter of the buttons and hydraulics.

Thanks for the heads-up, Russell!

Ok, these little routing guides are a great idea, Victor. I'd be inclined to just drill a round hole and then square up the edges with a chisel. That won't be as clean as this routing plan though.

How do find the cut edges on this board you're using for the horseshoes? That is, once you cut it, how much work does it take to get those cuts prepped so that they'll take paint and look smooth when they're finished. I'm pretty tempted to use plastic--ABS or PVC--for my horseshoe pieces when I start that step.

Matt McCormick

Matt,

If I understand your question correctly, I think you are asking about hiding the seams between the MDF layers. I will use Evercoat filler, and then sand that down smooth. It is similar to Bondo, but sands even smoother.

Let me know if I did not answer the question you were asking, though.

-Victor

Post a Comment