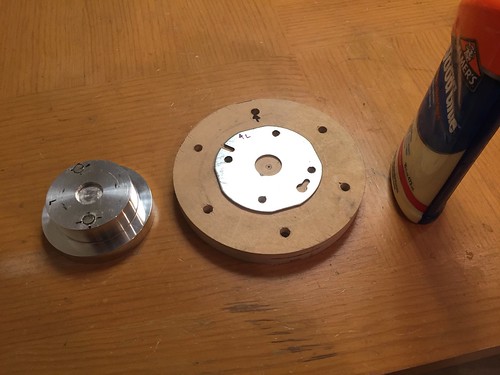

First up, the drilling. The holes on the 1" pipe flange for the outer pipe has its mounting holes a little too far apart to accommodate the magnets on the back of the shoulder hub. (The holes for the inner pipe's flange line up just fine with that shoulder hub's magnets.)

What's that glue for you ask? Oh, you didn't ask. Well, I'll tell you anyway. It's for my goofy method of determining where to drill holes in the backing plate.

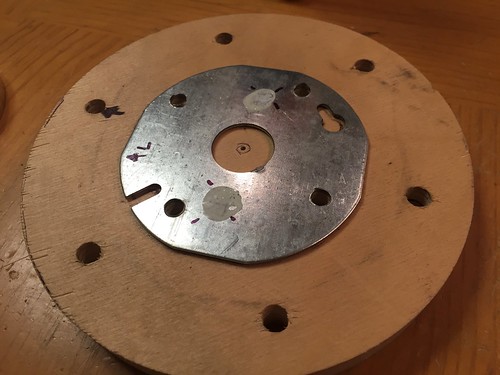

I put a drop of glue on each magnet, and then transfer that to the backing plate.

I told you it was goofy, but it does work.

I then used a pen to mark cross hairs around the glue on the backing plate, and wiped the glue off. Then, over to the drill press for some drillin'.

I drilled four holes in total, and then used some short wood screws to screw down some 1/4" nuts.

The magnets on the back of the shoulder hub stick nice and strongly to the nuts, so that part is out of the way.

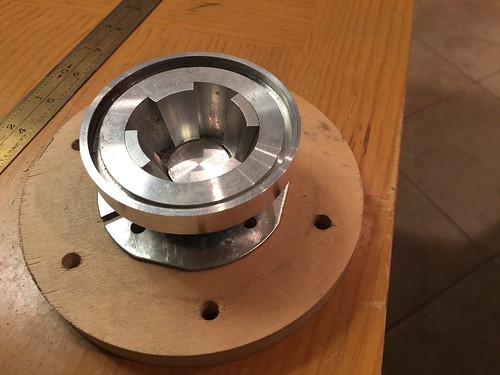

Next up, JB Welding the pipes into their flanges. First, I thoroughly cleaned the threads on the pipes and flanges with acetone and lots of paper towels and rubber gloves.

Shiny.

Next, I whipped up a batch of JB Weld epoxy, and applied it to the threads on the pipe. (With the back end of a plastic spoon, of course.)

I clamped the flange in a vise, and tightened the pipe as much as possible using a pipe wrench.

I repeated the process for the second leg, and I'll let these dry overnight (or however long it takes for me to get back to this.)

No comments:

Post a Comment