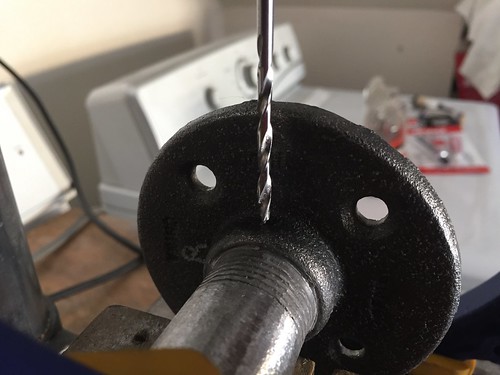

Here's my rickety setup.

I'm drilling a 1/8" diameter hole for the 1/8"x3/4" steel pin that will help lock the pipe and flange together.

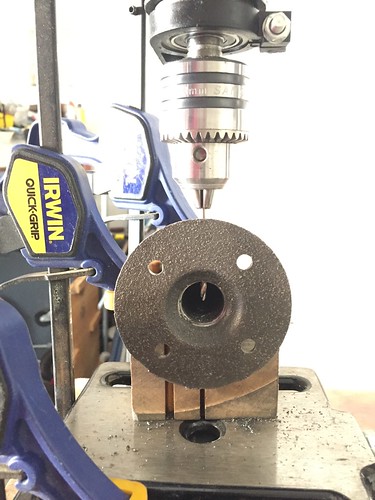

One down, seven more to go. (Three more for this flange, and four for the other.)

My goal was to align these holes every 90°, and by a little planning and a lot of luck, I mostly succeeded. (The drill bit was too short to drill completely through the pipe/flange in one shot.) It's not critical that the spacing be perfect, just a goal.

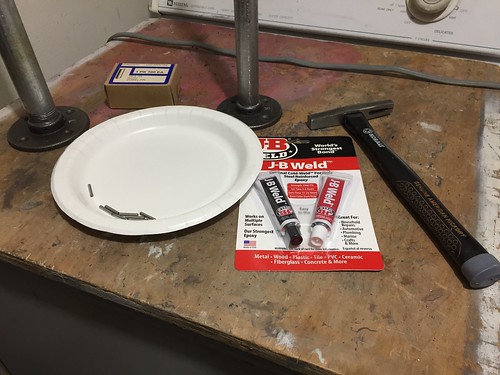

After I finished drilling all the holes, it was time to whip up a batch of JB Weld, and tap the pins in place.

And done.

And as a coda for the day, I exploded the droid so that I can start working on replacing the old pipe with the new.

I still need to drill holes in the shoulder discs to allow the motor wires to pass through, and I need to drill the holes for the bolts that will lock the gas pipes together. After all that, I'll need to file (or grind) a flat spot on the gas pipe, where the vertical rail that helps insure the 36° tilt. Hopefully I'll get to all that over the next few days.

No comments:

Post a Comment