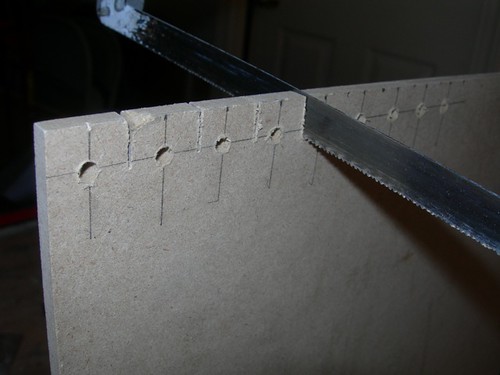

I drew a series of intersecting lines, about 0.7" apart and 0.4" from the edge of a board of MDF, and then drilled holes at the cross points.

I only need four of these, but I cut some extras just in case.

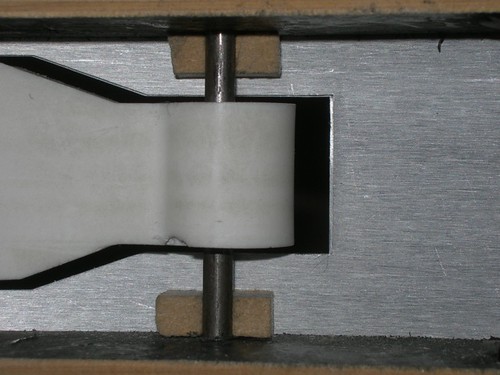

Next, the fun task of sanding these to size. I used a scrap skin panel to contour the MDF to the correct shape.

The theory is that the outside face of the utility arms should be flush with the outer skins. Likewise, the outboard edge of the MDF holder should be flush with the inside edge of the inner skin. Therefore, the MDF needs to be sanded until the two skin layers fit perfectly between the outer edge of the utility arm and the MDF holder.

And that's pretty much how it works out in practice, give or take a hundredth of an inch here or there.

I'm pretty happy with the location of the arms, I think they are pretty even with the skins. Nothing is holding it all together other than friction at this point. Soon I will JB Weld the pivot rods into the holes in the arms, and I'll glue the MDF to the ribs.

No comments:

Post a Comment