Big day today. Cut out the bottom and top bases for the wooden R2 frame, plus a circle from which I will make horizontal ribs. All of the information I gathered for this comes from Mike Senna's wooden frame tutorial on the Celebration II DVD from the R2 Builders Club, and from the companion tutorial found at

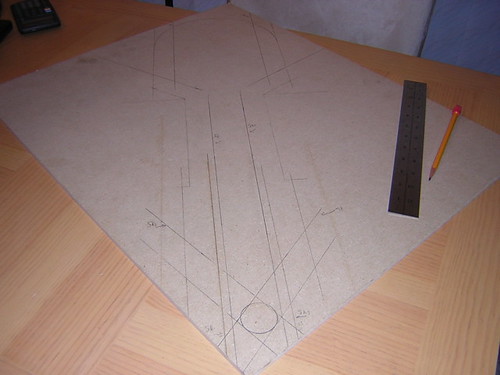

Wooden Frame TutorialFirst, I needed to cut a 4'x4'x3/4" section in half with the circular saw:

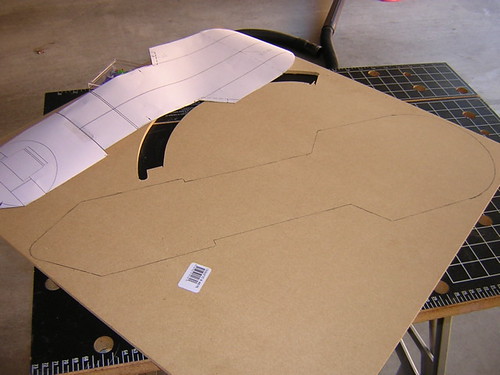

Next, I made a rough cut of the bottom base circle with a jigsaw, following a path just outside the penciled line that is 18" in diameter:

After that, I routed down the base circle using my circle cutter router attachment to bring the diameter down the exact diameter of the aluminum skins.

I did a test fitting of the skins to make sure the base circle was of the correct diameter. It was.

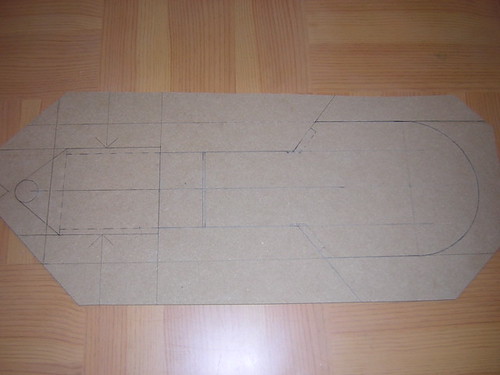

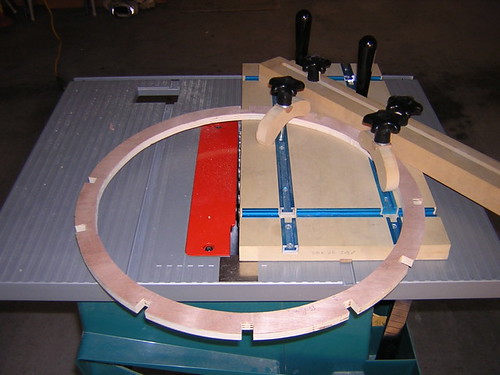

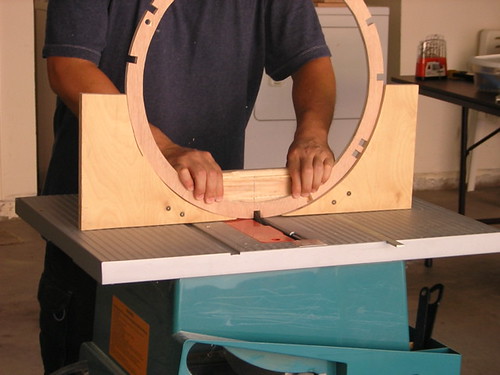

Next I worked on routing out the grooves for the vertical ribs. The location of the vertical ribs was determined by matching them up to the areas on the inside of the aluminum skins to see where a vertical could go. Only five of the ten vertical ribs go all the way from the bottom base to the top base.

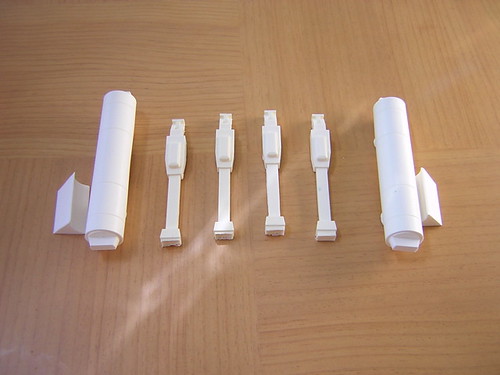

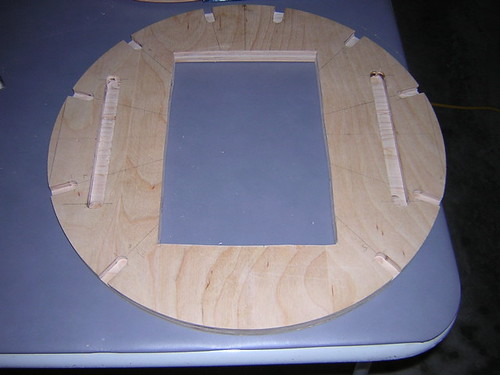

Then, I placed the ribs into the base for a test fitting. Pictures are of front and back. This took all day, my back is killing me.