We met at our rendezvous point at 7:00am to load the droids into the U-Haul truck that Thomas Roeoesli arranges. Our panel wasn't until 10:00am, but with street closures and traffic, we wanted to depart extra early. Thomas does an outstanding job of setting things up for the panel to go smoothly.

As we passed the convention center entrance on the way to the loading dock, we saw the thousands of people lining up to get into Hall H, where the huge panels take place. We haven't achieved Hall H status yet. Soon...

Once we arrived at the loading dock, we unloaded and wheeled our droids through the catacombs of the convention center, to get to Room 11 where our panel was to take place.

We had some time to kill, so we were able to visit the Millennium Falcon set that Michael McMaster worked on and got a group picture there. (Since Michael didn't bring a droid this year due to his involvement with the Magic Wheelchair project, he didn't need to arrive early.)

I took an opportunity for one of my favorite photos to get, from the vantage point of the escalator.

After that, it was time to start setting up in Room 11. We let the people who lined up early in, so they could get some pics of the droids as we got ready.

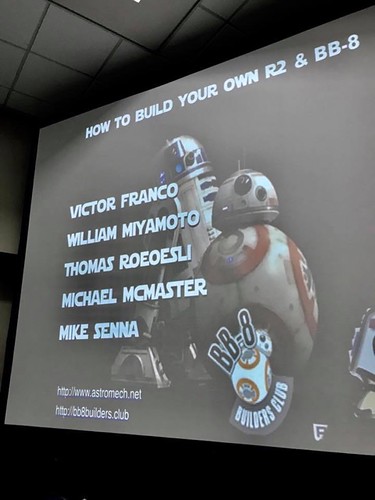

We started promptly at 10:00am. The panel covered both R2 and BB-8 building, hence the title slide.

I'm guessing the room held about 200 people, and it was pretty packed.

For the last few conventions, we've been using an Apple TV connected to the projector's HDMI port. I use my iPad to do the presentation, but it also allows Amy Senna to use her iPhone to show close-ups of the droids when we're demonstrating a gadget and such, and then I can take the screen back. (We password-protect the Apple TV so no one hijacks our presentation.) This works out pretty well.

We wrapped up with Q&A and one last panel selfie, and then it was time to pack everything up and book out of there.

It's always a neat experience to do a panel for San Diego Comicon, and hopefully we'll get to do it again next year.

Thanks to Amy Senna and Thomas Arroyo for some of the pictures here, and to Thomas Roeoesli for handling all the logistics to make the panel a success.